THE FEV PROJECT

FRANKENSTEIN ELECTRIC VEHICLE

UPCYCLE FOR GOOD

The MDA Group of companies is undertaking an ambitious project to produce an electric fleet of vehicles that is not only fit for purpose but also reduces our footprint on Papatuanuku (Earth Mother).

While electric vehicles provide a carbon-zero solution for emissions when in use, their production cost can be double the CO2 emissions of a similar internal-combustion-engine vehicle.

We are combating this particular issue by giving vehicles a second life, taking appropriate Recipient Vehicles, finding electric Donor Vehicles that are no longer roadworthy, and creating a Frankenstein Electric Vehicle (FEV).

We'll be detailing the build as we undertake this awesome project. Check in regularly to this page to see our progress, or keep an eye on our Insta and FB profiles for updates.

29 APRIL 2024: HERE'S AN IDEA.....

Back in 2019, we had put in motion a Fleet Policy that included raising the average age of vehicles to a maximum of 10 years (the previous concession holder for a transport route we now operate had vehicles that were 20-30 years old, upgrading to more efficient vehicles and beginning and electrification programme. However the pandemic that began in 2020 forced our group to halt asset investments in the interest of retaining as many staff as possible with no loss of income. While we were able to not only retain all our staff with no redundancies at full pay, our Fleet Policy was stretched to it's absolute limit with the electrification planning unfortunately left to gather dust.

Fast forward to 2024 and with a more stabilised visitor market and the recognition that we all need to be doing more for Papatuanuku, our attention has once again turned to an electrification programme for our fleet of around 20 vehicles. To kick off this ambitious project, we met with our good friend Ra Cleave. Ra is a bit of a mad scientist who seems to thrive with outside-the-box thinking, crazy ideas, and creating solutions that are for the betterment of our planet. The FEV Programme looks like it's going ahead.

07 MAY 2024: THE PILOT PROGRAMME

After a few catch ups it was time to head in to the forest to see where our first FEV would be operating, the Whakarewarewa Forest. The plan is to build an electric 4WD ute that is used as part of the Mountain Bike Rotorua Private 4WD Charter fleet.

After taking our existing vehicle (Toyota Landcruiser) out to test and assess things like terrain difficulty and fuel consumption it was time to try Ra's own FEV, a 1970's Mazda Bongo, for a drive in the forest.

With mountain bikers loaded and a computer attached, the team went out collected data to better understand power consumption and what can be expected on a typical work day for our fleet vehicles. We were also collecting information on what regeneration we could achieve when descending the hills. Whakarewarewa Forest vehicles are speed limited to 30kmph so what we found was that we could really dial up the regeneration ability of the Mazda when descending which had a few positive effects; more energy recovery and with the increased resistance the regeneration function acted like an engine brake which not only helped control our speed but will also, ultimately, save on brake wear and tear.

This was a great day out and we learnt lots by doing practical testing in the actual operational environment. It was now time for Ra to go and research the data he collected to start formulating a plan.

18 MAY 2024: NEXT GEN FLEET

Mountain Bike Rotorua Shuttles was now in to the next stages of fleet upgrades with the first of the new Private 4WD Charter vehicles purchased, a 2016 Ford Ranger certified with a 4inch suspension lift, 2 inch body lift, 3 inch tire size increase... basically every kids dream truck. The Toyota Landcruiser's could now be moved on and we could get to trialling the Ford Rangers as our new "Battle Waka" vehicles. This Ranger receives it's new nickname, Taniwha Waka.

One of the reasons we chose this particular make and model of vehicle is because they are very, very common here in Aotearoa New Zealand. This means that there are an abundance of parts available, many of the issues that they have are well known and are relatively easily identified and solved, and because of the chassis set up, there is a very solid platform to build an FEV on.

As a side note, after a bit of number crunching of the data that was collected while out testing the Mazda Bongo, Ra had found that when the regeneration capacity was increased during descents after a shuttle uplift, we were able to recover about 1/3 of the energy used to get up the hill. Our FEV may not get that much recovery as we'll be converting a much more complex drive train (to retain the 4WD capability). However it will still significantly improve the wear on brake pads which is most definitely a positive outcome.

12 JUNE 2024: TANIWHA WAKA

After a month of operations with the Taniwha Waka it was clear that not only would this work, but visitors were drawn to it and loved the charter experience. Now it was time to shop and find another Ford Ranger to become the Recipient Vehicle.

17 JUNE 2024: THE RV FOR OUR FEV THAT WOULD RECEIVE PARTS FROM A DV..... LOL

We found ourselves a suitable FEV recipient. A 2015 Ford Ranger Alltrak!

The Recipient Vehicle for our FEV was chosen for quite a few reasons:

-

Ford Rangers are the most sold, and therefore the most common utility vehicles in NZ. We can help develop a platform for giving broken down and aging second Rangers another life. Re-using old vehicles is an incredibly green option when considering moving to electric.

-

This particular ute has an aging engine that is showing signs of being near the end of its life.

-

It matches our existing fleet which means if we have successfully convert this vehicle, we could do the same to other fleet vehicles.

Our Donor Vehicle at this point is likely to be a Nissan Leaf. In discussions with Ra there is a key element to the Nissan EV set up that really appeals to us compared to Tesla's and BYD's. The Nissan Leaf battery, while much smaller than the other makers, makes for an excellent option for up-cycling as, unlike the other brands, we are able to relatively easily replace cells. This significantly reduces our footprint as we will be able to get more life out of each battery.

Like the Ford Ranger, there is also an abundance of Nissan Leaf vehicles and part in New Zealand.

02 JULY 2024: PLANNING THE PLAN

Ra has been working with a certifier on the planning and implementation stages, which have raised some areas for serious consideration, such as:

-

Gearbox: Originally an automatic transmission, the decision has been made to convert the truck to a manual and fix to second gear and use the High/Low ratio of the transfer box to switch between highway and off-road driving modes.

-

Battery: Mounting the battery will require some modification and fabrication, opting to place the battery just behind the cab and build a bespoke battery box attaching to the chassis.

-

Battery Cable: This requires lengthening, which may need to go to the Low Volume Vehicle Technical Advisory Committee for approval.

The certifier has provided valuable feedback, which has led to Ra being able to develop a robust plan, removing as many barriers as possible for a successful development and solid queries for the certifiers to consider.

Here are a few tidbits to mull over for those interested:

-

Current Weight: Front 1290 kg, Rear 1060 kg, Total 2350 kg (GVM 3200 kg)

-

Electrical Component Weights: Battery 280 kg, Motor, Inverter, Air Con, etc. 110 kg* (tbc), HV Cable 15 kg, Total 405 kg

-

Old Engine, Fuel Tank, and Fuel Weight: 320 kg

-

Net Increase of 85 kg, reduced carrying capacity from 850 kg to 765 kg

High Voltage Components for the FEV:

-

40kWh Battery Pack including BMS and relays

-

Power Distribution Module DC-DC Converter

-

Inverter

-

EM57 Electric Motor

-

Air Con Pump

Chassis Modifications:

Hangers only.

24 JULY 2024: FEV BUGGY TRIAL

We aren't reinventing the wheel here but we are trying something new for us. We're not the only ones trying cool things and investing in a greener future. Our whanau at Rotorua Rafting and Rotorua Ziplines have had a crack at developing their own FEV, but a bit different to ours.

A couple of years ago, working with Ra from Ripple Tech, Sammy Sutton (owner operator of the rafting and zip operations) set out to develop an eco-friendly return transport option for his zip line business he was developing. He bought a couple of recipient Yamaha 6 seat ATV's and a donor Nissan Leef to kick off the project..

There are a couple of advantages that they had when developing their FEV but the most notable being that they were operating off-road, which means there is no need to consider compliance to make the vehicle road legal. Great news if you don't need to do highway driving but not ideal if you need to both hit the highway and head off-road.

However, over the last few months, we've been working closely with the forest owners and managers and there may be an option in the future to have vehicles based near the forest. This is definitely a maybe but with an option like that being a possibility we wanted to explore what having an electric buggy in the forest might be like.

In a word, it was awesome!

Sammy was super kind and let us borrow his converted buggy. We have trialled ATV's before and have a protocol that we follow that was co-developed with Timberlands to be able to trial non-road legal vehicles in the forest. In short, we ensure that it is safe to operate, we get the vehicle covered by our insurer, we only use our approved, inducted, trained drivers and we provide a chase vehicle with a transporter attached to be able to load the buggy and move out of the forest if needed.

The electric ATV was seriously awesome. It was fun, practical and provided a heap of useful insights if we decide to go down this route. Ra is still crunching the data he collected but here are some initial impressions based on Sammy's past experience and the day of shuttling:

-

The suspension set up in the ATV was almost perfect, making for an even smoother ride than our Toyota Landcruiser Prado's we just sold. If you've owned a Prado you know that this is significant.

-

The current battery in the buggy needs cells replaced as it is currently only 60% and we ran it down to under 10% in 3 hours. New cells plus some tweaking of the regeneration could be more than enough to put the machine in the forest for a full day of shuttling, but Ra will work those numbers to see what it needs.

-

The ATV currently has 4WD capability but we didn't use this at all and it wasn't needed either. The power that the electric motor is outputting has been dialled down as it was breaking running gear so if we were to progress with a buggy, we would probably do away with 4WD and see what we can do to minimise breakages. Ra is consulting with Brad (who builds Drift Cars) to come up with solutions.

We are super grateful for the use of Sammy's electric ATV and we are excited that this is a possibility for future operations.

30 JULY 2024: STRIPPED NAKED AND GETTING MOCKED.... UP

The FEV is well underway with Ripple Tech's Ra Cleave now working side by side with local Rotorua international Enduro racer, Drift Car Racer, Whitewater Kayaker and all round Jack of All Trades Brad Lauder.

What does that mean you ask? Well, here is a brief synopsis of the build:

Main Vehicle: 2014 Ranger Alltrak, Inline 5 cylinder Diesel, Auto, 4WD

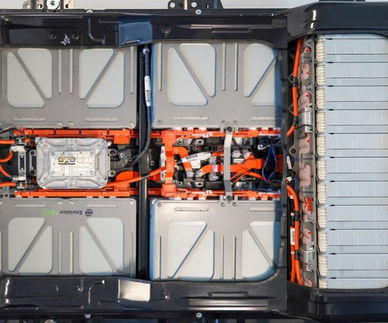

Donor Vehicle: 2018 Nissan Leaf, EM57 with 110kW inverter, 40kWh Battery

Effectively the Ranger will be stripped of the motor and associated parts, the transmission converted from Auto to Manual and then prepped to receive the donor vehicles motor in to the engine bay.

At this stage, the new electric motor is set be connected to the bell housing of the gear box, basically in place of the engine. In addition, the lads are intending for the battery to be fitted to the chassis using a bespoke sealed enclosure.

As you can see, the planning is well underway with a few different concepts for battery development and attaching the motor to the gear box being trialled (yes, that is timber you see there…. not a permanent solution, just a mock up).

With Brad now back firmly on Aotearoa NZ soil (he’s been racing Enduro overseas), him and Ra have metaphorically dived head first in to creating this monster.

06 AUGUST 2024: FABRICATION AND MODIFICATION PART 1

Racks off, tray off and the battery mounts and enclosure are coming together nicely. With the clever design, steering away from significant chassis modifications, certification while not easy, should be simpler than it could have been.

The Battery Cable has also been rigged up in to place. The cable has to be lengthened because the original Nissan Leef set up has the battery and the motor right next to each other with the battery running almost the length of the car under the cab. Our FEV has the motor in the engine bay and the battery placed behind the cab, meaning the high voltage cable needs the extra length of the Ranger double cab to be able to hook in to the battery. Because the cable is high voltage and not OEM (an original manufacturers part), it will need to be certified and as stated before, this may require approval of the Technical Advisory Board.

09 AUGUST 2024: MAWWIAGE IS WHAT BWINGS THE FEV TOGETHER TODAY...

Sooooooo.... it turns out that there are a heap of people interested in this conversion. 99% seem to be quite in to the idea too! We finally released the blog on our social channels and with that came a whole bunch of new followers.

We knew there were quite a few forums out there who passionately follow the NZ EV world but we didn't quite expect there to be so many people willing to provide input and advice. Very cool!

Anyway.... back to the update.... today is a great day. The final interface marrying the motor and the gearbox (coupling and tunnel) are now made and will be mounted in to the Ranger today!

This project is coming together well and the few hurdles that have been encountered thus far have been surmountable thanks to the collaboration between Ra, Brad and the regular updates with the certifier. Team, dreamwork etc. etc. Fingers crossed the road ahead remains smooth (pun totally intended).

19 AUGUST 2024: FABRICATION AND MODIFICATION PART 2

Progress continues and we are potentially only a couple weeks from being able to have some wheels spinning!

Engine Mounts: Brad has adapted a standard pair of engine mounts so they fit onto the Ranger chassis. After a bit of alloy fabrication we now have brackets to connect the electric motor to the mounts.

Battery Cable: A question popped up about this. As far as the cable goes, we've reused the RCS800 housing (aka the plastic plug) that the Leaf battery cable uses. We've bought single core cable (BFX 50 mm2), and found the RCS800 crimp connectors online. The end that goes into the inverter uses more standard lugs so that end is easy. It's quite important to have an EMI and earth shield around both cores, and this is terminated to the housings at each end. From there mechanical protection is provided by plastic conduit, and the final cable has to be supported every 350 mm.

Manual Gear Box: Some may say an EV is identical to the purists mountain bike, most a singlespeed….. Not us but some might haha.

The gearbox in EVs only has one gear ratio - usually a reduction in speed - and to go backwards you have to spin the motor in reverse. This is all good for an electric motor, but not an option for most combustion engines.

For this project the best mix of functionality, reliability, do-ability and cost was getting a Ford Ranger manual gearbox, throwing away the clutch, and locking the box in one gear just like a fixie! With the motor spinning at 5500 RPM second gear should give 80 kph when the transfer case is in high ratio and 40 kph when the case is in low ratio. This should be perfect for shuttling in Whakarewarewa.

11 SEPTEMBER 2024: From Birds Nest to Piece of Art

You might have noticed the slow down in blogging.... well it's not for lack of work or progress, but it's just that we're now on to "THAT" part of the build, the wiring.

So to recap on the last month or so:

-

The high voltage battery is now reconfigured with the battery management system hooked up back up.

-

The power steering pump is mounted.

-

The brake booster pumps are mounted.

Now there is a ton of wiring work to do which Ra is plugging away at. Stay tuned, we are not far away a working FEV...

29 OCTOBER 2024: TIME TO COMPLY...

Soooooooo, in between just trying to get the regular work done, having a bit of a getaway and the almost never ending job of wiring this sucker up, the E-Waka is now drivable.

While plans are likely to change in the future, the current idea is to get the Ranger looking like it did prior to the conversion. As you can see, it looks like a black Ford Ranger, job done...... for now.

It is now in Hamilton with the certifier awaiting the list of jobs to do to become compliant. Fingers crossed.